In today’s competitive packaging industry, preform production efficiency is a crucial factor that determines profitability, delivery speed, and overall factory performance. Whether you’re producing PET preforms for beverage bottles or specialized containers, every second of downtime or inefficiency translates directly into lost revenue.

This article outlines five proven optimization methods that help manufacturers achieve consistent output, lower costs, and longer equipment life without sacrificing product quality.

| No. | Strategy | Main Focus | Expected Benefit |

|---|---|---|---|

| 1 | Optimize Machine Settings | Fine-tune temperature, pressure, and cooling parameters based on resin and environment conditions. | 3–5% improvement in cycle efficiency without hardware changes. |

| 2 | Preventive Maintenance & Real-Time Monitoring | Regular inspections, use of sensors, and predictive analytics to prevent downtime. | Higher reliability and reduced unplanned maintenance costs. |

| 3 | Improve Mold & Cooling Efficiency | Upgrade mold materials, redesign cooling channels, and maintain cleanliness. | Up to 10% reduction in cycle time and improved product consistency. |

| 4 | Automate Handling & Inspection | Implement robotic systems and AI vision inspection for quality and consistency. | Reduced labor cost, fewer defects, and scalable production. |

| 5 | Train Operators & Data-Driven Management | Educate operators and use OEE tracking for continuous improvement. | Better process control, improved quality, and sustained efficiency gains. |

Fine-tuning the operational parameters of a preform machine is a crucial yet often underestimated aspect of achieving stable and efficient production. Even slight deviations in temperature profiles, injection speed, or cooling time can result in inconsistent wall thickness, part defects, and extended cycle durations — all of which negatively affect productivity and product quality.

By systematically analyzing production data and performing regular parameter audits, manufacturers can often unlock a 3–5% increase in cycle efficiency without making any physical hardware upgrades, simply through smarter process control.

A preform machine’s long-term reliability and productivity depend heavily on the health of its mechanical components. Establishing a preventive maintenance program not only minimizes unplanned downtime but also helps maintain consistent part quality and operational stability over time.

With the integration of predictive analytics tools, manufacturers can detect subtle performance declines in real time and implement immediate corrective measures, ultimately reducing repair costs and maximizing machine uptime.

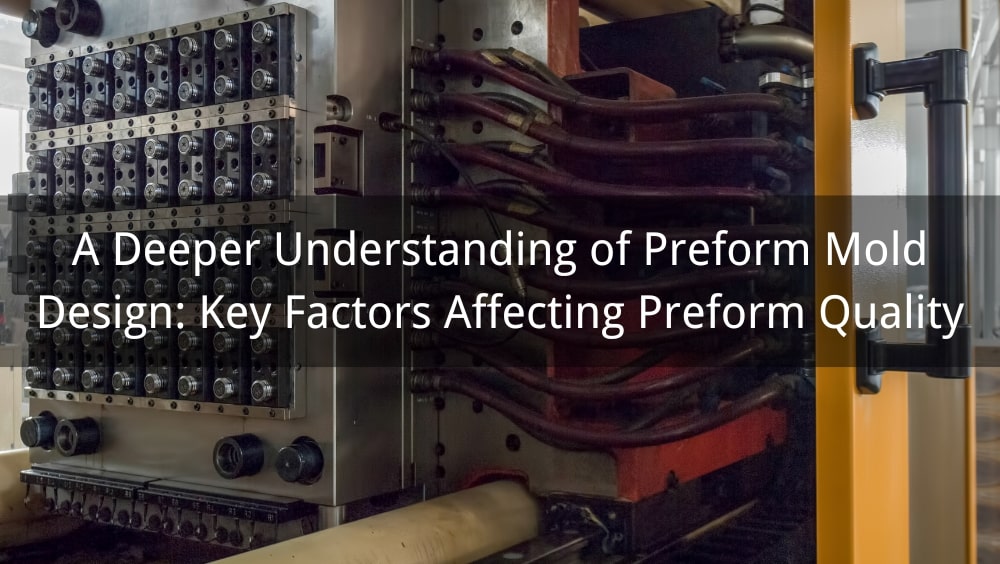

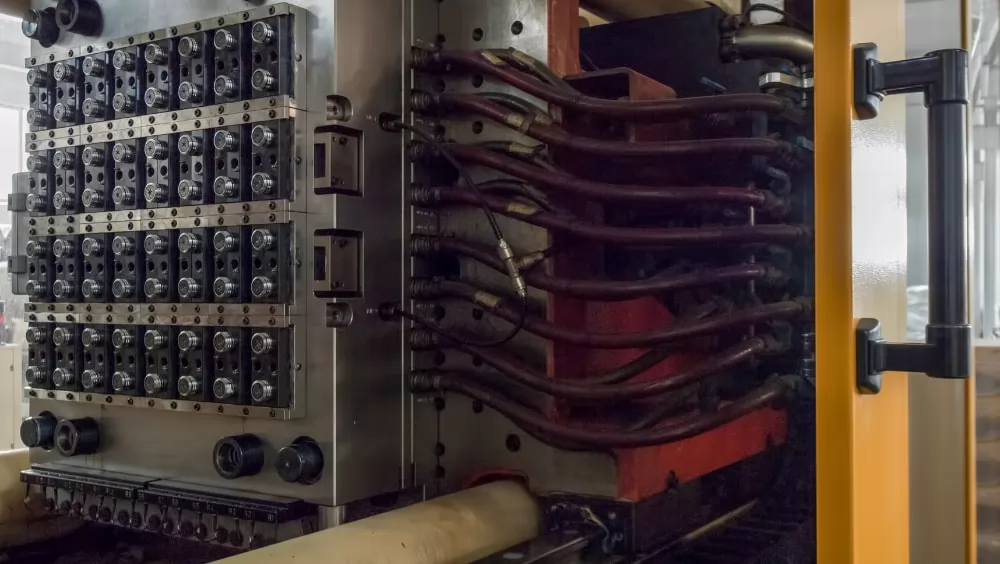

In preform production, the mold and cooling system form the core of both efficiency and product consistency. An intelligently designed and well-maintained mold can drastically shorten cycle times while ensuring excellent dimensional accuracy and surface quality.

By investing in modernized mold designs and advanced cooling solutions, many manufacturers report up to a 10% reduction in cycle time, leading to higher throughput and improved cost-efficiency across production shifts.

Manual handling of PET resin and finished preforms introduces unnecessary variability, contamination risks, and inconsistencies in drying — all of which compromise product quality. Automation enhances precision, reduces waste, and ensures repeatable performance across every production run.

Through automation, manufacturers can achieve more predictable and scalable operations, allowing skilled operators to focus on process optimization, analysis, and innovation instead of repetitive manual tasks.

Even the most advanced preform machine can only perform as well as the people operating it. A skilled, well-informed team — supported by real-time data insights — is the foundation of any high-efficiency production system.

When operators fully understand how their actions influence machine performance and output quality, both speed and consistency improve dramatically, fostering a culture of accountability and excellence throughout the production line.

Enhancing the production efficiency of preform machines brings more than just faster output — it drives long-term profitability, competitiveness, and sustainability. By making small but impactful improvements in machine operation, maintenance, and process control, manufacturers can achieve a higher level of consistency and performance across their entire production line.

Optimized machines can complete each cycle faster, allowing more preforms to be produced within the same time frame. This directly increases plant productivity without requiring additional machines or labor, maximizing the use of existing resources.

When efficiency improves, energy usage, material waste, and downtime all decrease. Lower energy consumption and fewer rejected preforms translate into tangible cost savings, helping manufacturers maintain healthy profit margins even in competitive markets.

Stable machine parameters and precise control over temperature, injection pressure, and cooling deliver consistent preform dimensions and appearance. This reduces defects, enhances bottle performance, and strengthens the overall brand reputation.

Efficient operation reduces mechanical stress and wear on machine components. Regular maintenance and optimized settings prevent overload, extending the service life of both the preform machine and molds, and reducing repair frequency.

Efficient machines run smoothly with fewer interruptions. Predictable performance allows production teams to plan output accurately, maintain steady delivery schedules, and respond quickly to customer demand without compromising quality.

Improving efficiency supports eco-friendly manufacturing. Reduced power usage and material waste help lower the carbon footprint of production, aligning the company with modern sustainability standards and environmental regulations.

High-efficiency production lines offer faster delivery, consistent quality, and better cost control — all of which strengthen a company’s position in the marketplace. It enables quicker response to new orders and improves customer satisfaction.

Ultimately, improving preform machine efficiency isn’t just about production speed — it’s about building a smarter, more sustainable, and more profitable operation that delivers long-term success in an ever-evolving manufacturing landscape.

Longer cycle times often result from improper temperature control, inconsistent cooling, or outdated mold design. Check temperature profiles, cooling channel flow, and ensure the mold is clean and balanced to restore optimal performance.

Basic checks such as lubrication and filter cleaning should be done weekly, while detailed inspections of injection units, clamps, and hydraulics should occur monthly. Preventive maintenance reduces downtime and keeps output consistent.

Yes. Automated material handling, resin drying, and vision inspection systems eliminate human error and variation. They ensure stable feeding, faster cycle transitions, and more consistent product quality across every production shift.

Focus on melt temperature, injection pressure, screw speed, and cooling time. Even minor adjustments in these areas can improve flow stability, reduce defects, and enhance overall cycle efficiency without hardware modifications.

Well-trained operators understand the relationship between settings, cycle stability, and product quality. Continuous training helps them identify issues early, optimize performance, and maintain smooth operation throughout the production process.

Improving preform machine production efficiency is not a single action but a continuous journey of adjustment and innovation. From optimizing settings and maintaining mechanical precision to redesigning molds, automating material handling, and training skilled operators, each improvement creates a cumulative impact. The key is consistency — using data, observation, and preventive measures to keep performance stable and predictable over time.

At FORAY, we believe that true efficiency comes from a balance of intelligent design and practical application. Our preform machines and system solutions are engineered to deliver superior precision, energy savings, and long-term reliability. If your goal is to achieve higher productivity with smarter technology, FORAY is ready to partner with you — bringing innovation, performance, and support that drive your production to the next level.