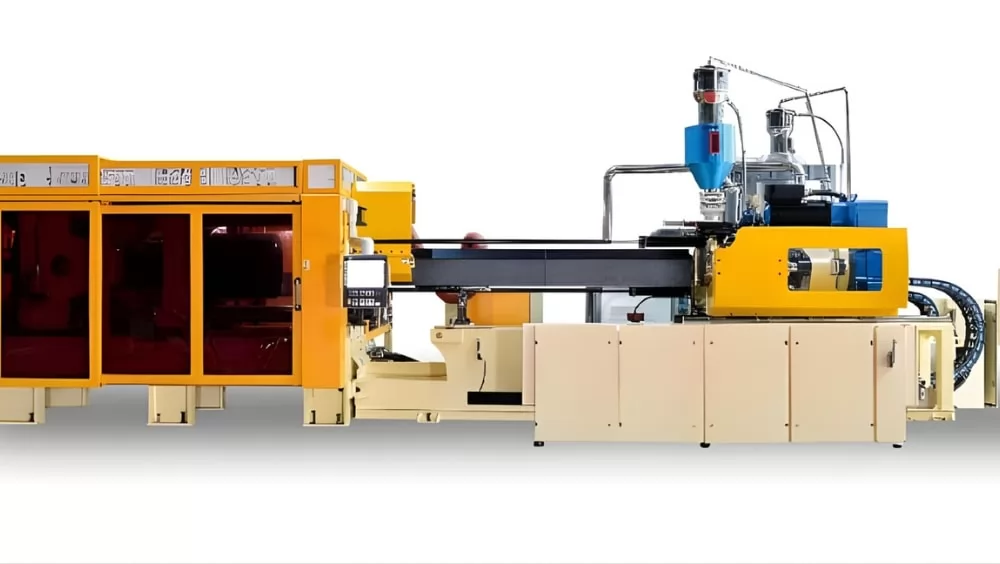

Choosing the right preform machine goes beyond technical specs—it affects product quality, cycle efficiency, and long-term costs. Many focus only on price, but the wrong machine can create persistent production challenges.

Understanding your product requirements, like preform weight, bottle size, wall thickness, and neck finish, is key. These factors determine the machine’s clamping force, injection capacity, and overall suitability for your production needs.

Also consider your production goals. Are you running high-volume batches, or do you need flexibility for smaller runs? Evaluating long-term scalability helps prevent costly upgrades later.

Every preform design is unique. Factors such as neck finish, weight, bottle size, wall thickness, and clarity directly affect machine selection.

Machines should handle the precise mold dimensions and apply consistent injection pressure to ensure uniform neck threads.

Heavier preforms require machines with higher clamping force and injection capacity.

Complex geometries or thick-walled designs may need specialized injection units to maintain flow and avoid defects.

By clearly defining your product requirements upfront, you can narrow down machine models that meet both technical and quality standards.

Clamp force and injection capacity are fundamental to machine performance. Proper clamping ensures molds stay securely closed during injection, preventing flash and deformation. Injection capacity must match preform volume and wall thickness to maintain consistent flow, reduce defects, and optimize cycle time. Machines with adjustable clamping and injection settings offer greater flexibility for different preform sizes and weights.

Preforms with varying wall thicknesses or intricate designs demand specialized injection units capable of maintaining uniform flow and preventing short shots. Machines designed for complex geometries provide precise control over injection speed, pressure, and temperature, ensuring consistent quality across every preform. Selecting a machine that can handle your product’s design complexity minimizes waste and rejects.

Mold compatibility is critical for efficiency and product accuracy. Reliable machines accommodate a variety of mold sizes and types, including multi-cavity and custom molds. Flexibility in mold installation, cooling channel design, and quick-change capabilities allows manufacturers to switch products with minimal downtime, improving production adaptability and reducing overall operating costs.

Beyond initial purchase price, total cost of ownership includes energy consumption, maintenance, spare parts, and labor. Machines with energy-efficient motors, automated monitoring, and preventive maintenance features lower operational costs. Evaluating efficiency metrics such as cycle time, yield, and uptime ensures that your investment maximizes long-term profitability and production consistency.

High-quality preforms require precise temperature control, uniform injection, and consistent cooling. Reliable machines often include real-time monitoring and feedback systems to detect deviations immediately. Combined with operator expertise, these features reduce defects, ensure dimensional accuracy, and maintain clarity and strength across every production batch, resulting in superior end-product quality.

Finding a trustworthy preform machine supplier is crucial for ensuring consistent product quality, efficient production, and long-term operational reliability. A reliable supplier provides not only high-quality machinery but also technical support, maintenance guidance, and process optimization advice.

Look for suppliers with a proven track record in the PET preform industry. Check client testimonials, case studies, and years of operation to gauge reliability and expertise.

A strong supplier offers comprehensive support, including installation assistance, operator training, and prompt troubleshooting. Quick and effective after-sales service minimizes downtime and production losses.

Choose suppliers that provide a wide variety of machine models and can tailor solutions to your specific product requirements, including neck finish, wall thickness, and production capacity.

Ensure the supplier adheres to international quality standards and certifications. Compliance with safety and environmental regulations reflects their commitment to reliability and long-term performance.

A financially stable supplier is more likely to provide continuous support, spare parts, and upgrades. Building a long-term partnership ensures consistent access to technology and expertise.

By carefully evaluating experience, technical support, product range, certifications, and financial stability, you can select a preform machine supplier who will support your production goals effectively and reliably.

| Machine Model | Key Factors | Advantages | Price Range |

|---|---|---|---|

| Model A | Lightweight preforms, small bottles | High precision, fast cycle time, energy-efficient | $50,000 - $70,000 |

| Model B | Medium weight preforms, standard bottles | Robust construction, moderate cycle time, easy maintenance | $70,000 - $100,000 |

| Model C | Heavyweight preforms, large bottles | High clamping force, capable of complex geometries, durable | $100,000 - $150,000 |

| Model D | Custom or specialized preforms | Flexible mold compatibility, precise injection control, scalable production | $120,000 - $180,000 |

Choosing the right preform machine model requires balancing product specifications, production efficiency, and budget considerations. Each model offers unique strengths, whether it is high precision, heavy-duty capacity, or flexible mold adaptability. By carefully analyzing your requirements and understanding the advantages of each machine, you can optimize your production line and achieve consistent preform quality with minimal waste and downtime.

Evaluate your preform’s weight, bottle size, wall thickness, and neck finish. Match these specs with machine clamping force, injection capacity, and mold compatibility to ensure optimal performance.

Some machines are flexible and support various sizes, but highly specialized designs may require dedicated models. Check mold adaptability, injection units, and automation capabilities before deciding.

Cycle time affects productivity and cost. Faster machines with efficient cooling and precise injection control can improve throughput without compromising quality. Match speed to production targets.

Yes. A machine with lower energy consumption and easier maintenance reduces operating costs over time. Evaluate total cost of ownership, not just initial purchase price, for long-term savings.

Choose machines with precise temperature control, uniform injection, and real-time monitoring. Proper operator training and preventive maintenance also help maintain consistent quality and reduce defects.

Selecting the right preform machine ensures consistent quality and efficient production. Aligning your choice with product requirements reduces defects, scrap, and downtime.

Energy efficiency, automation compatibility, and flexibility for future product changes are also important. A well-chosen machine supports both current operations and long-term growth.

FORAY offers preform machines designed for precision, efficiency, and durability. Partnering with FORAY helps manufacturers achieve consistent preform quality and optimize production, ensuring their operations stay competitive.