Do you want a powerful PET preform injection molding machine to improve your work efficiency? What should you look for when buying a new PET preform injection molding machine? What is the "right" PET preform injection machine?

With these questions, this article will help you. We will help you determine which type of injection molding machine is best for your needs and what issues you should consider when buying a preform molding machine.

When choosing a preform injection molding machine, consider several factors. Your choice will largely depend on your specific needs and the intended application of the machine. Here are the key aspects to weigh before investing:

The first and foremost aspect to consider is your budget. Injection molding machines can vary significantly in price based on their capabilities, size, and brand. Determine how much you are willing to spend and what features are non-negotiable within that budget. A clear budget will help narrow down your options and prevent overspending.

Understanding the specific types of bottles and containers you intend to produce is crucial. Different pet preform injection machines are designed to handle various shapes, sizes, and materials. Knowing your product specifications helps ensure that the machine you choose can accommodate your production needs without compromising on quality or efficiency. This ensures compatibility with your production goals and minimizes the risk of purchasing a machine that cannot meet your requirements.

Determining your required machine capacity is essential for efficient production planning. Capacity involves considering the volume of preforms you need to produce within a given time frame. This helps you select a machine that can handle your production demands, avoiding underutilization or overworking the machine. A pet preform injection machine with the right capacity ensures optimal performance, reduces downtime, and meets your production targets consistently.

Evaluate the size and weight of the machine to ensure it fits within your production facility. The physical space available, the layout of your production line, and the machine's weight are all important factors. A machine that is too large or too heavy for your space can cause logistical issues and impact efficiency.

After-sales service and support are crucial when purchasing an pet preform injection molding machine. Reliable after-sales service ensures that you can get help with installation, maintenance, and any issues that arise during operation. Check if the manufacturer or supplier offers comprehensive support, including training, spare parts availability, and prompt technical assistance.

The type of injection molding system is another essential factor. Hydraulic systems are generally more powerful and suitable for heavy-duty applications, offering high clamping forces. However, they can be noisier and less energy-efficient. All-electric systems, on the other hand, are quieter, more energy-efficient, and offer greater precision and repeatability, making them ideal for high-precision and energy-sensitive applications. Consider the specific needs of your production process when choosing between these two systems.

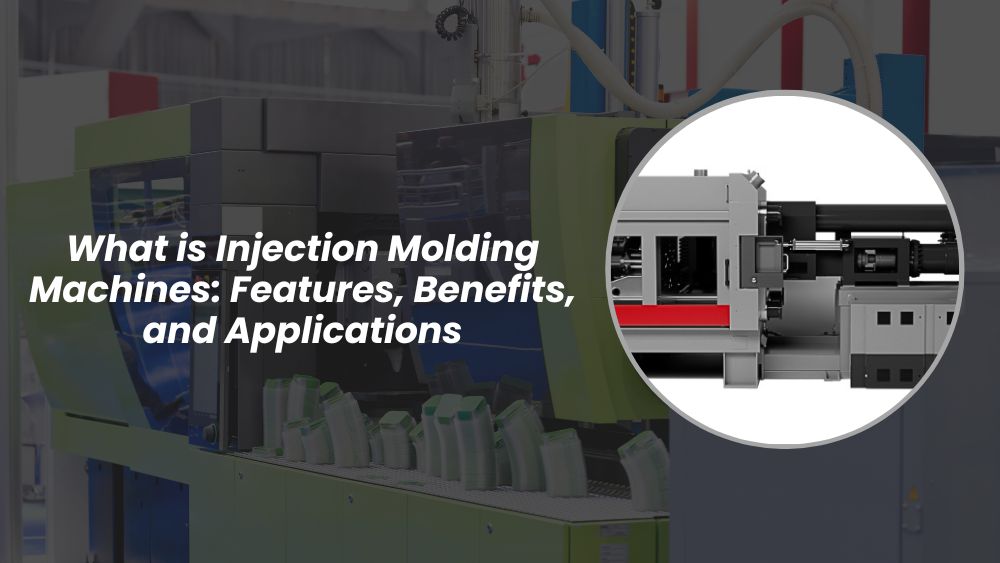

ProPET direct pressure injection molding machine, as an outstanding new-generation model, with numerous practical patented technologies. Developed by our research and development team through years of market research and technical refinement. It meets customer demands for high quality, high production capacity, ease of maintenance, and sustainable applications.

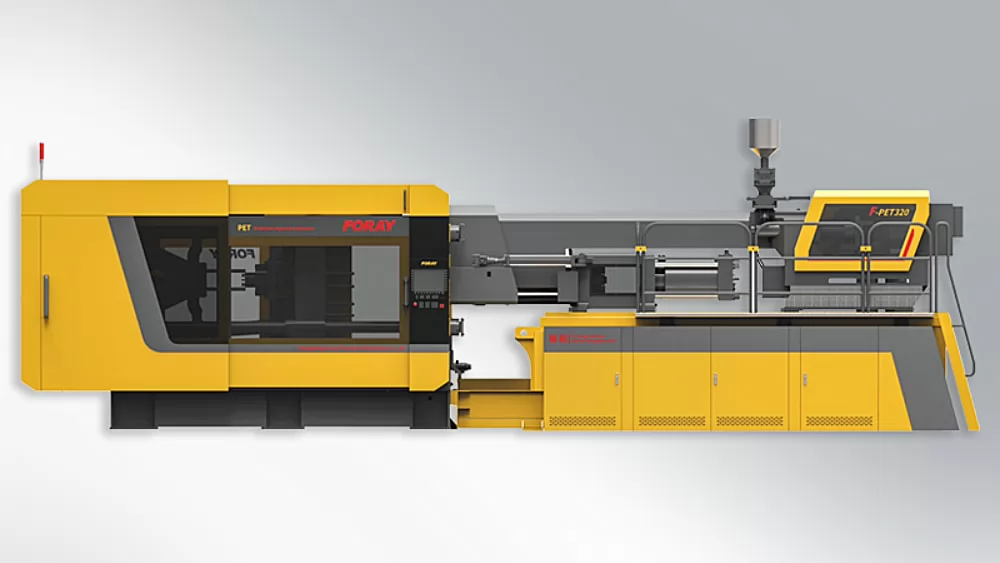

F-PET high-speed injection molding machine optimized unit configurations,and it can compare with the international high-end equipment in product quality, production efficiency, and energy consumption. Delivering outstanding product quality, they meet the demands of customers seeking high quality, high production capacity, and cost-effectiveness.

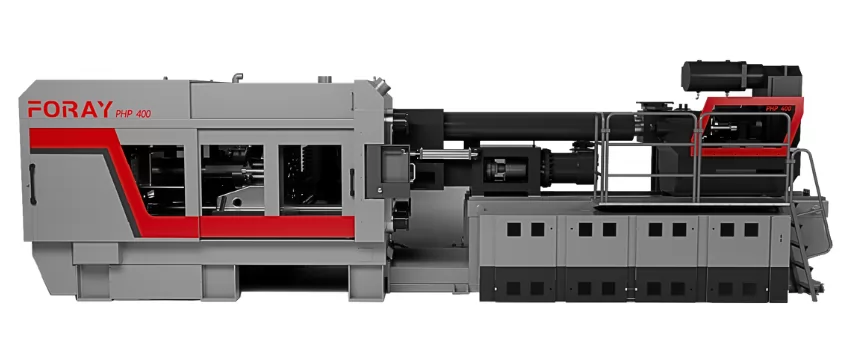

This series of injection molding machines has the following outstanding advantages: low investment cost, high-cost performance, and strong practicality. It is especially suitable for customers with many product specifications, many molds, and medium output of heavy weight products.

E-PET standard injection molding machine adopts efficient screw design and servo systems, our injection molding machines are more efficient and energy-saving than common market models. Ideal for a wide range of industry applications, they cater to customers seeking economic practicality with moderate production volume requirements.

This basically sums up our article on how to choose the right preform injection molding machine. Once you figure out what kind of work you need the machine to do, you just need to look at the relevant specifications of the machine.

When in doubt, ask the experts. At FORAY, we are the leading preform machine supplier in China, providing high-performance injection molding machines to users around the world.

From precision preform injection molding machines to high-speed all-electric injection molding machines, our molding machines can meet all the needs of your project. If you need our service or help, please contact us today!