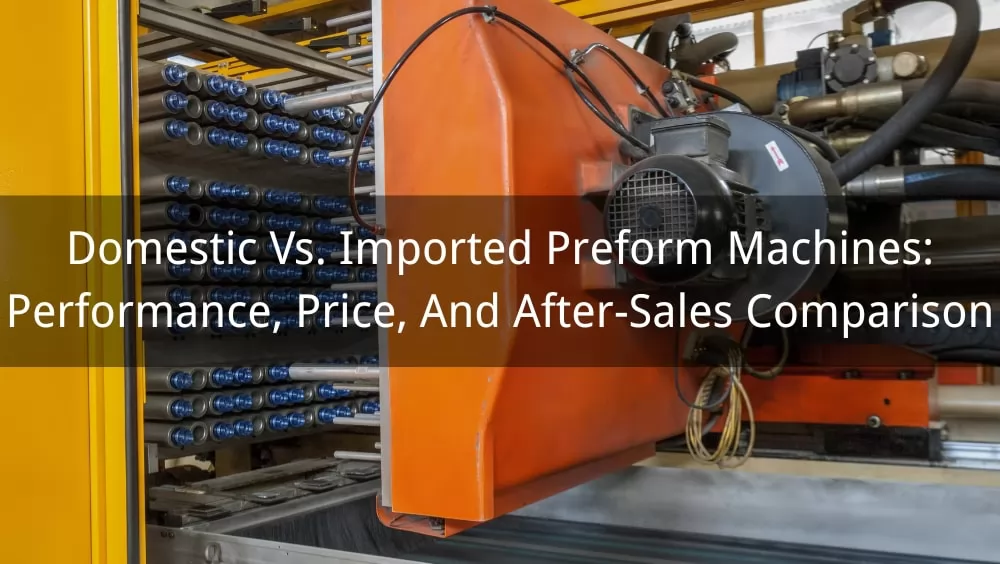

In the competitive landscape of preform manufacturing—whether for plastic bottles, industrial components, or composite materials—the choice of production equipment plays a pivotal role in determining efficiency, cost-effectiveness, and long-term operational success. Among the most critical decisions manufacturers face is whether to invest in domestically produced preform machines or imported alternatives. Both options come with distinct advantages and trade-offs across performance, pricing, and after-sales support, making it essential to evaluate them holistically based on your specific production needs.

This article provides a detailed, structured comparison of domestic and imported preform machines, breaking down their differences in technical capabilities, cost structures, and service ecosystems to help you make an informed purchasing decision.

Preform machines are specialized equipment designed to produce preforms—intermediate components that are later molded into final products through processes like injection stretching blow molding (ISBM) for plastics or hot pressing for composites. These machines directly influence:

Given these critical roles, selecting the right machine—whether domestic or imported—requires a thorough analysis of your production scale, material requirements, and long-term business goals.

The performance of a preform machine is defined by its ability to consistently deliver high-quality outputs under varying operational conditions. Here’s how domestic and imported machines typically compare:

Strengths:

Limitations:

Strengths:

Limitations:

Cost is a decisive factor for most manufacturers, but it’s essential to look beyond the sticker price and consider the total cost of ownership (TCO), including maintenance, energy consumption, and potential downtime.

Upfront Costs: Typically 30%–50% lower than imported equivalents, making them an attractive option for small to medium-sized enterprises (SMEs) or startups with limited capital.

Total Cost of Ownership:

Upfront Costs: Generally 2–3 times more expensive than domestic machines due to import duties, shipping fees, and currency exchange fluctuations.

Total Cost of Ownership:

Key Insight: For low to medium production volumes, domestic machines often provide better cost efficiency. For large-scale, high-precision operations, imported machines may deliver long-term value despite higher upfront costs.

Reliable after-sales support is critical for minimizing downtime and ensuring consistent machine performance. Here’s how domestic and imported providers typically differ:

Advantages:

Challenges:

Advantages:

Challenges:

Key Insight: Domestic providers excel in responsiveness and accessibility, while imported brands offer superior technical expertise—but often at the cost of speed and convenience.

Selecting between a domestic and imported preform machine requires more than a simple price comparison — it involves a strategic assessment of your production goals, technical requirements, and long-term business vision. Each option carries its own balance of strengths and trade-offs, and the most effective choice is one that complements your factory’s scale, workflow, and quality expectations.

Production Scale: For small to medium-volume operations, domestically manufactured machines typically deliver strong performance at a lower investment cost, making them ideal for companies focused on local markets or gradual growth. In contrast, for large-scale, high-throughput production lines that demand precision and consistency across multiple shifts, imported machines often justify their higher initial costs through superior automation and operational endurance.

Product Complexity: If your products involve standard preform shapes with moderate precision requirements, domestic machines generally offer excellent reliability and ease of maintenance. However, for advanced or complex components—such as lightweight, thin-walled preforms or multi-layer applications—imported machines excel with advanced engineering features, tighter tolerances, and greater automation flexibility.

Budget Constraints: When financial resources are limited, domestic machines provide a highly practical balance between affordability and performance. Their lower upfront cost and reduced maintenance expenses make them particularly suitable for startups or growing manufacturers. On the other hand, businesses prioritizing long-term efficiency, energy savings, and advanced process control may find that imported machines deliver a stronger return on investment over time.

After-Sales Priority: Fast and reliable after-sales service can make or break production continuity. Domestic providers often stand out in this area, offering local support teams, readily available spare parts, and immediate response times. Meanwhile, imported brands may provide deeper technical expertise and global support systems, though at the cost of longer response times and higher maintenance logistics.

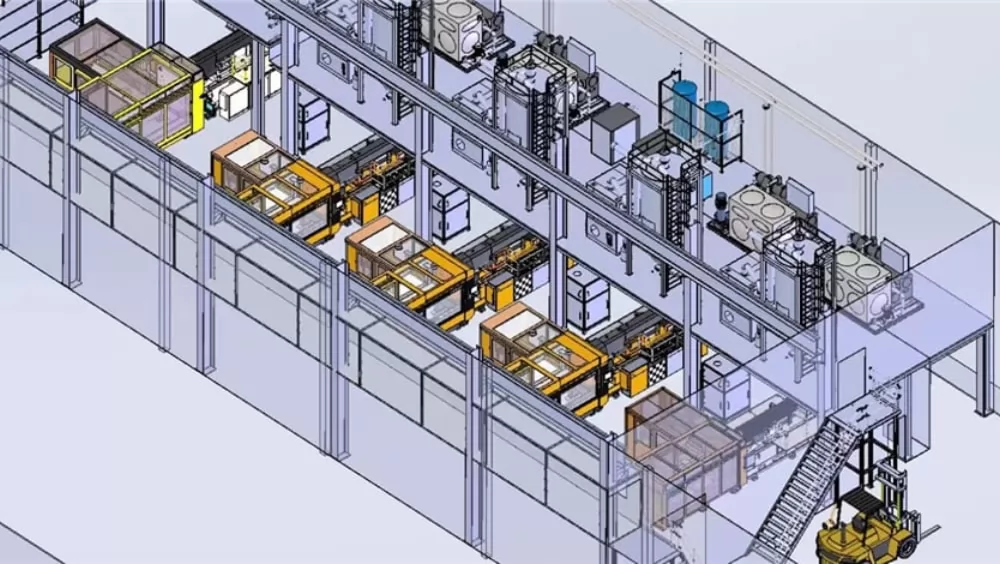

Ultimately, the right decision depends on your unique operational priorities. Many manufacturers find success with a hybrid approach — utilizing domestic machines for standard production tasks where cost and responsiveness matter most, and deploying imported models for specialized lines that require the highest levels of precision, durability, and innovation.

Selecting between a domestic and imported preform machine requires more than a simple price comparison — it involves a strategic assessment of your production goals, technical requirements, and long-term business vision. Each option carries its own balance of strengths and trade-offs, and the most effective choice is one that complements your factory’s scale, workflow, and quality expectations.

Production Scale: For small to medium-volume operations, domestically manufactured machines typically deliver strong performance at a lower investment cost, making them ideal for companies focused on local markets or gradual growth. In contrast, for large-scale, high-throughput production lines that demand precision and consistency across multiple shifts, imported machines often justify their higher initial costs through superior automation and operational endurance.

Product Complexity: If your products involve standard preform shapes with moderate precision requirements, domestic machines generally offer excellent reliability and ease of maintenance. However, for advanced or complex components—such as lightweight, thin-walled preforms or multi-layer applications—imported machines excel with advanced engineering features, tighter tolerances, and greater automation flexibility.

Budget Constraints: When financial resources are limited, domestic machines provide a highly practical balance between affordability and performance. Their lower upfront cost and reduced maintenance expenses make them particularly suitable for startups or growing manufacturers. On the other hand, businesses prioritizing long-term efficiency, energy savings, and advanced process control may find that imported machines deliver a stronger return on investment over time.

After-Sales Priority: Fast and reliable after-sales service can make or break production continuity. Domestic providers often stand out in this area, offering local support teams, readily available spare parts, and immediate response times. Meanwhile, imported brands may provide deeper technical expertise and global support systems, though at the cost of longer response times and higher maintenance logistics.

Ultimately, the right decision depends on your unique operational priorities. Many manufacturers find success with a hybrid approach — utilizing domestic machines for standard production tasks where cost and responsiveness matter most, and deploying imported models for specialized lines that require the highest levels of precision, durability, and innovation.

The debate between domestic and imported preform machines ultimately comes down to balance. Imported models may excel in precision, stability, and global reputation, while domestic machines often lead in cost efficiency, adaptability, and local support. The key is to align your choice with your production goals, technical needs, and after-sales expectations.

Beyond price and performance, after-sales service can make or break your long-term satisfaction. Domestic manufacturers typically provide quicker technical response and localized spare parts, minimizing downtime. Imported models, though reliable, may face longer lead times for service or maintenance. Weighing these trade-offs carefully ensures you choose a solution that keeps your operations running smoothly.

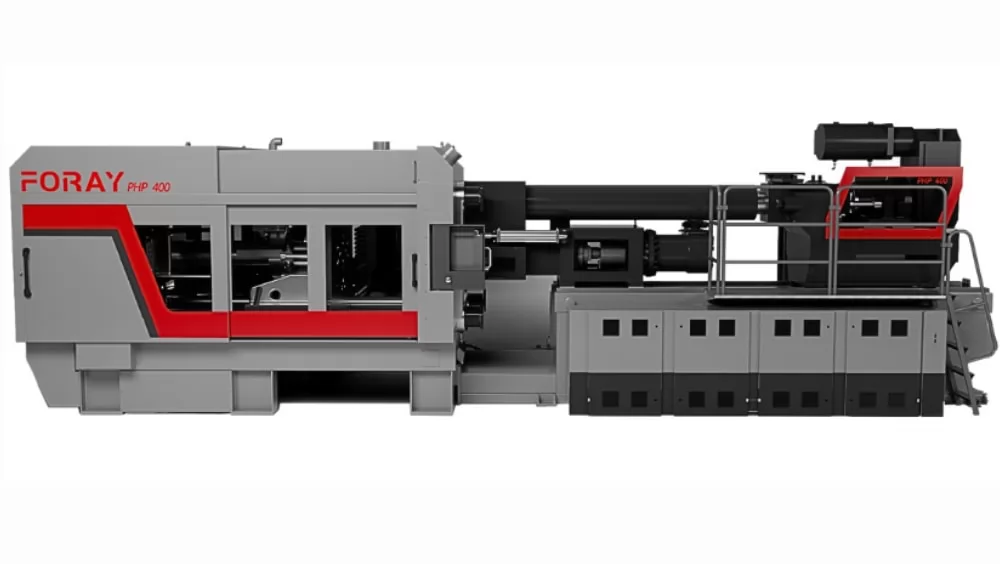

For manufacturers seeking a balance of world-class performance, affordability, and dependable support, FORAY delivers exactly that. With precision-engineered preform machines designed for stability, energy efficiency, and consistent output, FORAY combines the quality you expect with the service you can rely on. Choosing FORAY means investing in technology that performs—and a partner committed to your success.