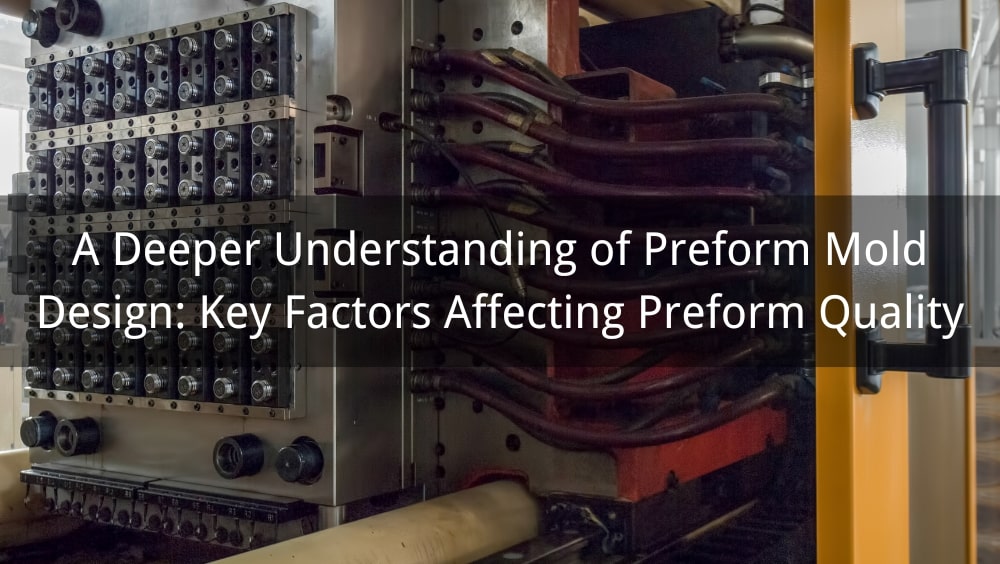

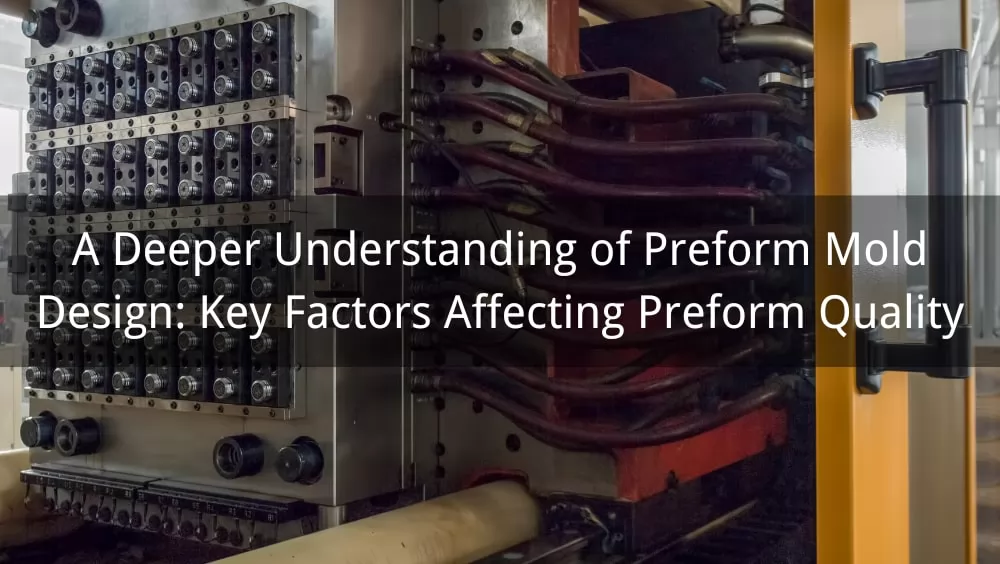

In PET preform production, the mold is not just a tool — it’s the foundation of consistent quality, cycle time, and durability. Even with the most advanced injection molding machines, poor mold design can lead to uneven wall thickness, haze, warpage, or increased scrap rates.

Understanding the science behind preform mold design helps manufacturers strike the perfect balance between precision, cooling efficiency, and mechanical strength. This article explores the key design factors that directly influence preform quality and production efficiency.

Preform molds are specialized tools used to shape raw materials (such as plastics, metals, or composite fibers) into an intermediate form—"preforms"—that are subsequently processed (e.g., injected, compressed, or cured) into final components. Unlike end-use molds, preforms are designed with specific goals: controlling fiber orientation in composites, pre-distributing molten plastic for balanced flow, or establishing precise geometries that reduce material waste during final forming.

The quality of the preform directly impacts downstream processes. For instance, an improperly designed preform mold may lead to uneven material distribution, internal voids, or weak stress points—all of which compromise the structural integrity of the final product. As such, preform mold design is not an afterthought but a proactive engineering discipline that requires balancing material behavior, process constraints, and end-use requirements.

Designing an effective preform mold demands a holistic approach, addressing both macro-level structural considerations and micro-level details. Below are the key factors that determine preform quality:

The choice of mold material is dictated by the production volume, operating temperatures, and the nature of the raw materials being shaped. Common mold materials include:

Additionally, the mold surface finish (ranging from mirror-polished to textured) influences material flow and part release. For example, a smooth finish is critical for preventing drag marks in plastic preforms, while a textured surface might be used to enhance adhesion in composite layups.

Preform molds must be designed with exacting dimensional accuracy to ensure the intermediate component meets the required specifications. Key considerations include:

Advanced CAD/CAM tools enable designers to simulate material flow and stress distribution, identifying potential weak points before the mold is manufactured.

Temperature control is a cornerstone of preform quality. Inefficient cooling can lead to prolonged cycle times, warping, or incomplete curing, while inconsistent heating (for thermoset materials) may cause uneven polymerization. Effective mold design incorporates:

Trapped air or gases during the molding process can create voids, burn marks, or weak spots in the preform. Proper ventilation design involves:

Different manufacturing processes impose unique demands on preform mold design:

Engineers must tailor the mold design to the specific process parameters, such as injection speed, compression ratios, or curing temperatures.

A well-designed preform mold prioritizes ease of maintenance to minimize downtime and extend operational lifespan. Features include:

Regular maintenance—such as polishing worn surfaces or replacing damaged cores—ensures consistent performance over thousands of production cycles.

As manufacturing technology continues to advance, preform mold design is rapidly evolving to meet higher performance and sustainability standards. Modern manufacturers are exploring innovative methods to improve precision, shorten development cycles, and minimize costs while maintaining product consistency.

One of the most notable trends is the integration of additive manufacturing and digital twin technology. 3D printing allows engineers to create complex mold geometries quickly and affordably, while digital twins enable virtual simulations that predict mold behavior, optimize cooling efficiency, and identify potential defects before production begins.

In addition, the shift toward sustainable materials—such as recycled metals and biodegradable polymers—is reshaping mold manufacturing. These eco-friendly choices reduce environmental impact and operational costs, paving the way for greener and more efficient preform production in the future.

Mold temperature directly impacts wall thickness, surface finish, and dimensional accuracy. Incorrect temperatures can cause warping, uneven shrinkage, or inconsistent material flow.

Efficient cooling channels maintain uniform mold temperature, reducing cycle time and defects. Poor design can lead to hotspots, uneven thickness, and slower production.

Mold material affects thermal conductivity, durability, and precision. High-conductivity metals improve cooling efficiency, while durable alloys ensure long-term dimensional stability.

Yes. The shape and flow paths inside the mold determine how material fills the cavity. Poor geometry can create air traps, uneven thickness, and surface defects.

Regular cleaning, polishing, and inspection prevent wear, corrosion, and residue buildup. Proper maintenance ensures consistent preform quality and extends mold lifespan.

Mold design is the foundation of preform quality. From cavity precision to hot runner balance and cooling efficiency, every detail impacts clarity, strength, and consistency. Ignoring these elements can increase waste and costs, while careful design can elevate production to new levels of reliability.

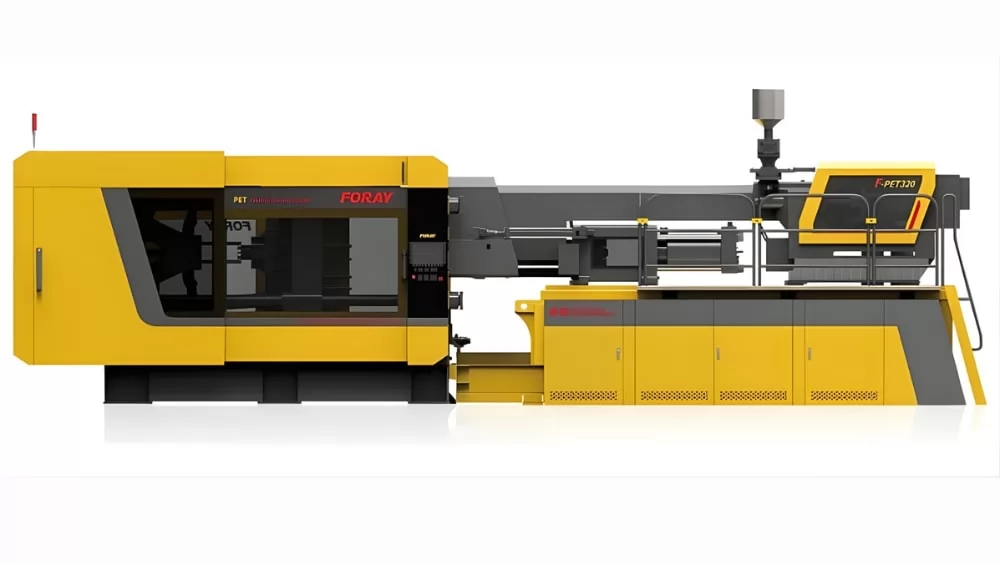

For manufacturers seeking advanced mold solutions, FORAY provides expertise in precision engineering, thermal management, and durable materials. Partnering with FORAY ensures consistent preform quality, reduced downtime, and optimized efficiency—helping your production lines stay ahead in a competitive industry.